No two commercial or industrial operations are alike. Even enterprises working in the same industry will have different production requirements that necessitate unique processing equipment. That's why custom built devices are worthy investments – paying for complete industrial design and fabrication means you get a solution optimised for your business alone. Cutting down into these benefits further, here are three reasons to commission custom industrial equipment instead of choosing a pre-fabricated solution.

1. Custom made means custom purpose

Equipment commissioning involves considering the specifications of your enterprise operations and determining the individual components needed to make everything tick. Ask yourself specific questions about your production system:

- Does your production process involve weighing output?

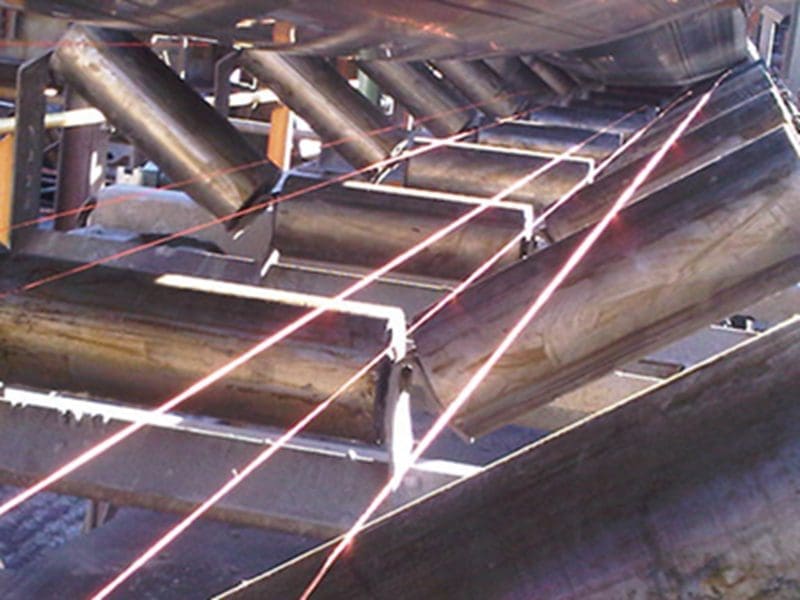

- Are conveyor systems required for moving materials between different points?

- Do you need safety assurance checks such as metal detectors or X-ray equipment?

Once you've answered these questions, custom designing a production system seems the best way of fitting each of your requirements. Whatever your needs, custom design for mining and industrial applications means you'll be delivered a system entirely fit-for-purpose. This translates to higher savings and productivity thanks to reduced time spent managing production quirks or training employees on using outside-supplier equipment. This gives your business a unique edge and purpose.

2. It's cost–effective

The most significant cost for industrial operators is purchasing the initial plant needed to build a total production system. It's an issue unique to mining and industrial applications and means every dollar spent on processing equipment should be measured against long-term value.

Industry-leading pre-fabricated weigh and measure solutions are excellent base points for building a more complete production system – but any gaps in system cohesion translate to costs down the line. That's why equipment commissioning is so cost-effective. It means each component, every individual item of plant, was selected and custom designed to meet the unique needs of your organisation.

3. You form lasting enterprise partnerships

A quick purchase works well for businesses timewise. But choosing a pre-fabricated solution over a custom designed processing system often means industrial operators forgo the chance to build lasting enterprise partnerships with the best in their industry.

Once a pre-fabricated item becomes worn from wear-and-tear or is in need of repair, the relationship with your product supplier becomes crucial. A custom designed system means the service team will know every inch of your operations, how each piece fits together and when repairs can be turned into opportunities for long-term upgrades. These valuable partnerships can lead to other services such as equipment financing or retrofitting, offering industrial businesses much more than a one-off job can.

SRO Technology is a leading supplier of weigh and measure solutions to industrial and commercial operations nationwide. With a client base spanning multiple sectors and a system design team boasting decades of experience, we've seen it all. That means we can develop a custom production system that meets your precise enterprise requirements in a cost- and time-effective manner.

To get the process started, reach out to the SRO Technology team today by clicking below.

Recent Comments