When you operate a facility with lots of machinery and equipment, ensuring everything is working to full capacity is vital to reaching maximum output. But not all operations managers have the time or can afford to conduct a thorough site audit. An inspection of your measurement solutions and other equipment can mean downtime and may reveal wear-and-tear to be worse than you hoped for. So does your facility need a site audit?

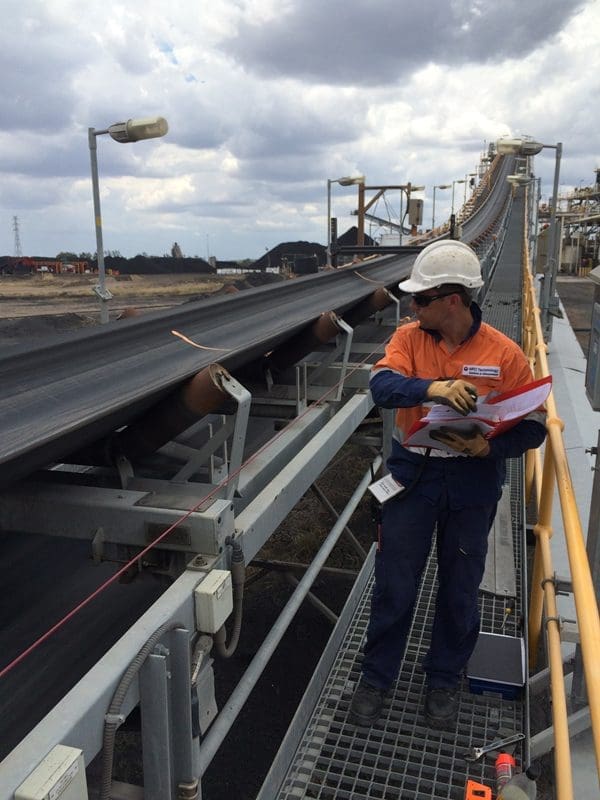

A thorough look over your equipment is worth the investment and vital for any industrial processing businesses that want a clean bill of health. Today, SRO Technology looks over the three reasons your facility needs regular site audits.

Often the repeated use of weighing and detection equipment can leave them inaccurate or imprecise. SRO Technology's extensive experience in performing site audits has led to our discovery that around one in 10 of the sensors and measurement equipment in an industrial processing site function incorrectly or require recalibration. By checking on your equipment, you can save yourself thousands in potentially producing faulty goods that need to be replaced later.

Checking your dynamic belt weighing system will ensure that weight readings are accurate and prevent costly measurement mistakes. Additionally, checking your tramp metal detector ensures it accurately scans for even the most minute amount of metal, guaranteeing a quality product for your customers.

2. Ensuring staff know-how

In regularly performing site audits, you can not only ensure the equipment and measurement solutions you rely on for everyday operations are in working order, you can also check your staff and management are up to date on how to get the best out of this equipment. Take downtime during a site audit as an opportunity to refresh your floor staff's knowledge or upskill them.

For example, conducting a site audit of your facility's X-Ray machines is a good opportunity to ensure all operators are up to date with any health and safety information they need. SRO's X-Ray detection systems are an excellent solution to scanning for unwanted impurities in your products – but only if operated safely.

3. Ensuring you know your own facility's potential

Seeing the benefits of regular site audits come from being able to look over your entire business at once. Often, it takes an opportunity to step back and see the bigger picture to convince you that you are ready to take the next step and expand. A site audit allows you that thorough overview of all the measurement solutions and other equipment on site – this means you can see what machinery needs to be replaced or upgraded.

Doing this will help improve your facility's productivity or save you time.

Contact SRO Technology for a through site audit

Having a thorough look over your facility's measurement solutions and other equipment is vital to reaching full productivity – so contact the team at SRO Technology today for more information on our site audit services by clicking below.

Recent Comments