Australia's red meat industry could benefit by up to $420 million per year if objective measurement technology were to be fully adopted across the sector, according to an independent report by Greenleaf, Miracle Dog Consulting and S. Williams Consulting. However, the benefit is only likely to be around $72 million per annum by 2020, based on current adoption rates.

"There is an enormous amount of value that's currently being lost to our industry."

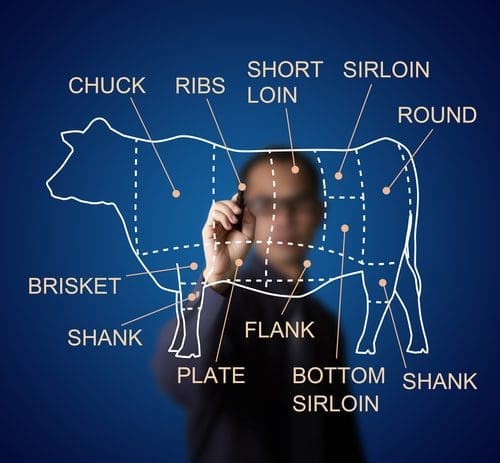

It's all about lean meat yield

The Meat and Livestock Australia (MLA)-commissioned report estimated that 65 per cent of the potential financial gain would be a direct result of measuring lean meat yield.

Richard Norton, managing director of Meat and Livestock Australia, said the findings highlight just how valuable objective measurement technology could be to the sector, especially if there is a complete roll out.

"As the report shows, there is an enormous amount of value that's currently being lost to our industry through inaccurate measurement or appraisal systems within the red meat supply chain," Mr Norton said.

"That's why MLA has been working hard with industry to develop solutions, including our proposal to fast track the adoption of DEXA technology as an objective measure of lean meat yield in meat processing plants."

DEXA is capable of measuring the amount of meat, fat and bone in a carcass.

What is DEXA?

DEXA – short for Dual Energy X-ray Absorptiometry – has long been used in the healthcare industry to measure body fat composition and bone density.

Applied to the meat industry, DEXA is capable of measuring the amount of meat, fat and bone in a carcass and offering a more accurate way to determine payments to producers than existing approaches.

The MLA has put together a proposal for a DEXA rollout in Australia which it says will help realise more of the potential benefits sooner, rather than later.

"MLA's proposal will pave the way for scientific measurement of saleable meat yield, future-value based marketing and industry-wide productivity gains through processing automation, genetic improvement and data-based on-farm decision making," said Mr Norton.

"This is a solution for the whole of the Australian red meat value chain."

"This is a solution for the whole of the Australian red meat value chain."

Ensuring accurate weight and product safety in the meat industry

Once meat has been assessed for its quality and is ready for processing and packaging, that is where SRO Technology comes in.

Using the latest technology, our checkweighers facilitate responsible food production and can accurately weigh products up to 68 kilograms. They feature extremely accurate in-motion scales that can be automated with the objective of checking product weights that fall within the correct predefined limits.

SRO Technology also supplies the most reliable and accurate X-ray detection systems in Australia. These systems are designed to detect physical contaminants such as glass, stone, metal and other solid objects, in packaged foods, unpackaged foods and bulk goods foods. Using such technology enables businesses to be assured of their quality control procedures.

Partner with SRO Technology

With more than 20 years of experience providing measurement solutions to a wide variety of industries, SRO Technology has developed a deep understanding and knowledge of what is required in the development of product measurement and inspection instrumentation specific to different sectors.

SRO Technology offers a range of customised services. Whether you are looking for a checkweighing system alone or a combination of weighing and X-ray detection within one system, our experts will be able to come up with a practical and cost-effective solution.

If you'd like to find out more, please contact SRO Technology today.

Recent Comments