Speed Sensors

SRO Technology understands the importance of the correct speed feedback and has a number of speed sensor solutions to match your requirements.

Accurate and reliable speed feedback required to measure belt travel with minimum slippage is key to accurate and repeatable weighing. SRO Technology understands how important this is to get the best out of your application. As not all installations are able to use the same speed sensor there are a number of different solutions to cater for location, availability and budget.

Our Solutions

Thermo Scientific Ramsey Model 60-12C

Read more

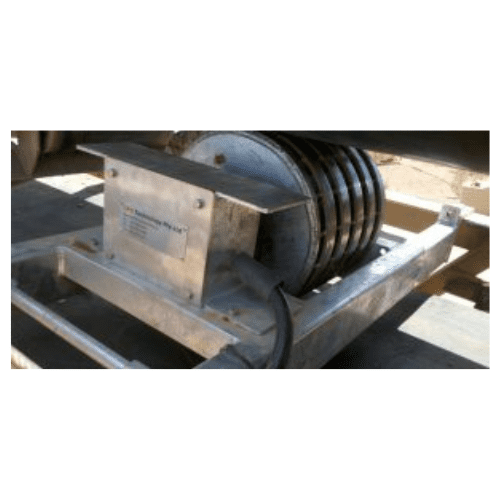

Thermo Scientific Ramsey Model 60-12 This sensor is the most reliable and accurate speed-sensing device ever developed for belt scale service. Direct-coupling the sensor to the conveyor tail pulley, snubbing roll or a large diameter return roller ensures accurate belt-travel readout. Its rugged, cast-aluminum housing makes it suitable for outdoor installations. It comes equipped with an AC pulse generator, so there are no brushes to adjust or replace. This unit can also be adapted to run on the ruturn belt as a trailing arm.

60-12c- 20 to 200 RPM

60-12F -3 to 30 RPM

Multispeed - Precision Belt Speed Reference

Read more

SRO Technology supplies a highly reliable Spiral cage precision conveyor belt speed reference for Process Measurement and Bulk Materials Handling. This precision speed reference is suitable for high accuracy, inventory belt weighers, distance to tramp measurement for metal detectors and continuous belt speed monitoring. The system uses a self-cleaning open spiral cage pulley which contacts the clean side of the belt.

- High accuracy-Proximity switch or Ramsey 60-12c

- Self cleaning

- Greasable bearings

- Suit belt widths 600 – 2400mm with belt speeds from 0.1 -6.5m/s

Trailing Arm - Belt Speed Reference

Read more

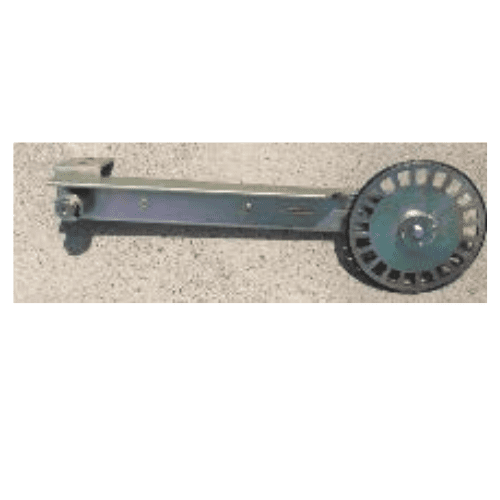

The trailing arm type speed sensor uses its own weight and friction between the rubber outer ring of the friction wheel on the return side of the conveyor belt to rotate the wheel. Holes in the friction wheel allow a proximity switch to pick up a pulse from the wheel as it rotates. The unit is designed to mount off a cross beam near to the belt scale using the pivoting bolting bracket mounted off the trailing arm unit.

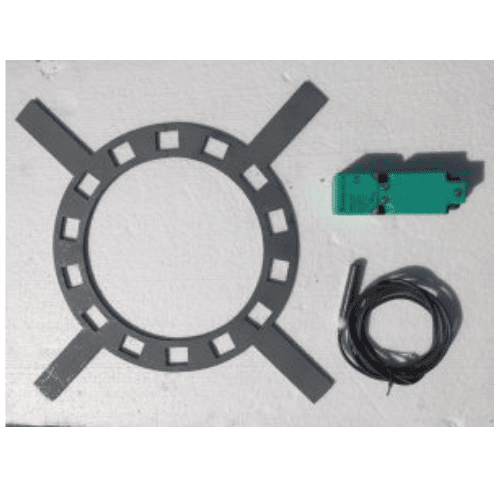

Proximity Switch & Target Plate

Read more

Mounted on the tail pulley of the conveyor this solution provides a direct speed feedback to the beltscale.

- Easy to install on any diameter tail pulley

- M12 Barrel prox as standard

- Optional 20mm block prox, or site standard

- Low cost

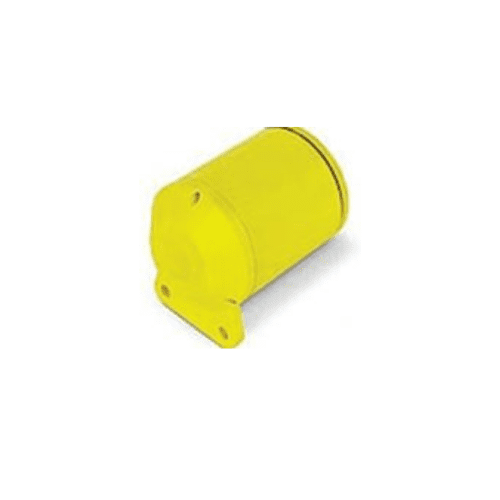

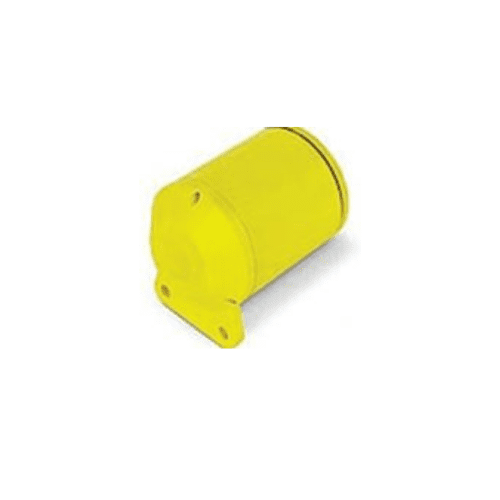

THERMO SCIENTIFIC RAMSEY MODEL 60-12P

Read more

Thermo Scientific Ramsey Model 60-12P Proximity Speed Switch Mounted on the tail pulley of the conveyor this solution provides a direct speed feedback to the beltscale.

Heavy Duty construction for the harshest of environments

Easy to install

Frequency : 0-3000 Pulses/min.

THERMO SCIENTIFIC RAMSEY MODEL 60-23P UNDER SPEED SWITCH

Read more

Thermo Scientific Ramsey Model 60-23P Under Speed Switch This switch monitors the rotational velocity of a shaft or another type of rotating equipment. It may be used on conveyor belts, bucket elevators and other types of rotating equipment. Heavy duty design means its ideal for harsh working environments.

Frequently Asked Questions

What are speed sensors used for in industrial applications?

Speed sensors provide accurate and reliable feedback on belt travel to ensure minimal slippage, crucial for precise and repeatable weighing in various industries.

What types of speed sensors does SRO Technology offer?

SRO Technology offers a range of speed sensor solutions, including the Thermo Scientific Ramsey Model 60-12C, Multispeed precision belt speed references, Trailing Arm belt speed references, Proximity Switch & Target Plate, Thermo Scientific Ramsey Model 60-12P, and Thermo Scientific Ramsey Model 60-23P Under Speed Switch, catering to different requirements based on location, availability, and budget.

How do speed sensors work?

Speed sensors can be directly coupled to conveyor tail pulleys, snubbing rolls, or return rollers for accurate belt-travel readout, use self-cleaning spiral cage pulleys for high accuracy, or employ friction wheels and proximity switches for speed monitoring, depending on the model.

What are the benefits of using speed sensors in conveyor systems?

Speed sensors ensure the efficient operation of conveyor systems by providing critical speed feedback, enabling accurate process measurement, bulk material handling, and preventive maintenance through under-speed detection.