Conveyor Belt Scales

Australia-wide solutions for conveyor belt scale systems.

At SRO Technology, we design, supply, install and maintain high-precision conveyor belt scales (also known as belt weighers or weightometers) to suit a wide range of industrial applications. Our belt scale systems help ensure accurate load monitoring, efficient material flow, and reliable process control across sites nationwide.

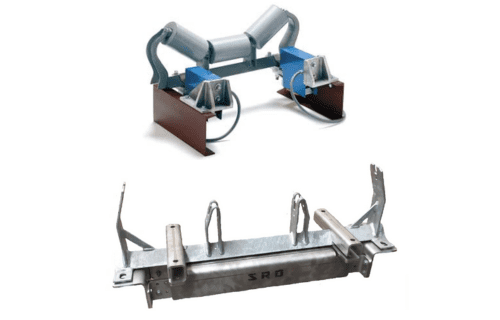

Our Belt Scales are Australian Made.

From welding and cutting to painting and assembly, our skilled technicians in Brisbane and Sydney handle every step, while our engineers across the country ensure precise installation.

Our services

With over three decades of industry experience, SRO Technology delivers end-to-end solutions – from supply and installation to calibration, verification, and ongoing maintenance.

We are the trusted experts in conveyor belt scale systems and understand that they do more than measure mass and flow rate. They play a critical role in:

- Verifying material loads for accurate invoicing.

- Managing batching and blending systems.

- Auditing material use and flow.

- Improving operational efficiency and reducing waste.

Conveyor belt weighing solutions

Precision weighing

Our Ramsey conveyor belt scales offer exceptional accuracy – up to ±0.25%, ideal for high-precision industrial processes.

Process weighing

We supply a wide range of Ramsey solutions for monitoring and controlling the flow of bulk materials across production lines.

Custom weighing

Need something unique? We offer custom-engineered systems for weighing, feeding, metal detection, and spare parts – all optimised for seamless integration.

Our process

Design and installation

We work closely with your team to engineer and install systems tailored to your site’s layout and operating conditions.

Calibration and verification

We perform scheduled maintenance and calibrations every 12 weeks, ensuring systems remain accurate and compliant with trade requirements.

Ongoing support

From breakdowns to system upgrades, our technicians offer responsive, on-site support to keep your operations running smoothly.

Why choose SRO?

We have experienced and qualified technicians nationwide, offering you fast, localised support. Our systems are proudly Australian-Made and we can design tailored conveyor belt scale weighing systems that fit your unique operational needs.

We provide site-specific recommendations and have the capability to service a wide range of scales, because if a product is still serviceable, there’s no need to replace it.

Where we service

We provide a comprehensive conveyor belt scale service including supply, maintenance, breakdowns, retrofitting, servicing and auditing across Australia – including rural and remote areas and all capital cities.

Industries we serve

Agriculture and Grain Handling

Mining and Resources

Scrap Metal Recycling

Get in touch

Ready to experience our Dynamic Weighing services? Contact our Dynamic Weighing team today on 07 3395 6136 or email us at service@srotechnology.com to learn more about how we can support your business.