Level measurement is crucial for process control in a number of industries. These systems help businesses to work out how much product is being used in manufacturing, whether there's a risk of overfilling or if levels are too low. Solutions can even be used to detect blockages.

As many will understand, the aforementioned blockages and overfilling instances can pose a serious problem for businesses. Blockages can damage expensive and critical equipment, while overfilling can result in chemical, ore and other material spillage. In effect, level measurement is just as useful for risk mitigation as process control.

Given just how important level measurement is, businesses will understandably want to utilise only the best solutions. But, with such a large number available, what's best?

There's no one measuring solution that's applicable to every situation.

Choosing a measuring solution

Every business has different level measuring requirements, and this is best seen when comparing the food and mining businesses. Food production businesses will in many cases need to measure liquids, while mining businesses will find that measuring solids in dusty environments is more common.

There's no one measuring solution that's applicable to every situation. Fortunately, there's a significant number of instruments available.

Radar

Ideal for water and sewage applications, radar measuring instruments work extremely well in liquid environments. This means they're one of the better options if a business is working with liquids.

Key industries: Sewage and waste water, food and chemicals.

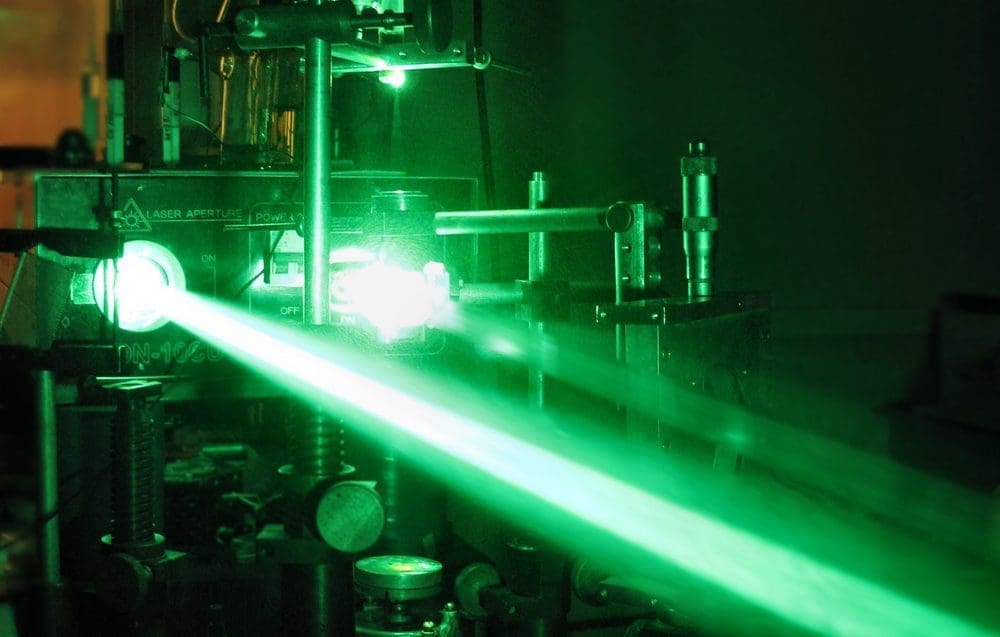

Laser instruments

These are more expensive measuring solutions than radar, but they are significantly more versatile. Laser instruments can accurately detect both liquids and solids, all without coming into contact with the product. Being contact-less also has a number of other advantages over alternative measuring solutions. For example, being able to calculate measurements at any required angle.

Key industries: Mining, power generation, chemicals, food, pulp and mining.

Ultrasonic instruments

Taking a different approach to the radar and laser instruments explained above, ultrasonic measuring instruments instead use sound pulses to work out the volume of a liquid in a particular bin or storage solution. Sending out sound pulses four times per second, it's easy for the solution to accurately identify the volume.

Like laser instruments, these are also resistant to corrosion as they don't come into contact with the measuring devices.

Key industries: Sewage and waste water, food and chemicals.

Weight instruments

Lastly, there are weight instruments. These require contact with the products in order to calculate volume, but they're also quite versatile. Weight instruments can measure bulk solids and liquids, and also handle pulp, pellets and mining material.

Key industries: Mining, food and agriculture.

An understanding of the available solutions doesn't necessarily mean a business is ready to implement them, however. It's nearly always safer and faster to work with a professional team of experts.

We work hard to generate reliable and consistent results and add value to your operations.

The SRO Technology approach

SRO Technology have an experienced team of engineers and technicians ready to help you select the best measuring instruments for your particular application. This capability is an important part of how we approach design and implementation.

Over the course of any project, we work hard to generate reliable and consistent results and add value to your operations. We also only use measuring solutions that are capable of withstanding tough environments.

If you're interested in learning more about the technologies detailed above, then it's time to get in touch with the team at SRO Technology.

Using best in class solutions paired with experienced professionals is the best way to approach any project.

Recent Comments