Belt Scales

Showing 1–9 of 12 results

-

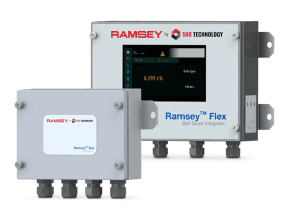

Ramsey Flex Integrator v1.5 Pro

-

Ramsey Flex Integrator v1.5 Plus

-

Ramsey Flex Integrator v1.5

-

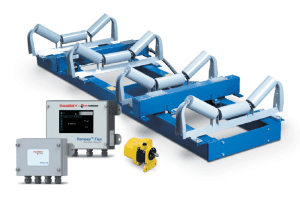

Ramsey Flex Belt Scale Integration Solution

-

Ramsey IDEA Belt Scale System

-

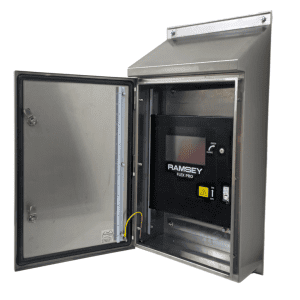

Ramsey Micro-Tech 9100 Electronics Platform

-

Ramsey Micro-Tech 9101 Electronics Platform

-

Ramsey Micro-Tech 9301 Electronics Platform

-

Ramsey Series 14 Belt Scale Systems