Density Gauges

Geiger Counters

Gamma Survey Meters

People working in the industrial sector understand the importance of measuring liquid or slurry density.

Natural variation in the raw feedstock materials alters the composition of the product being processed, resulting in production or quality issues. Companies can even lose money or suffer from unexpected disruptions as a result of inaccurate density readings. The comprehensive robust range of Thermo Scientific Nucleonic Density Measurement instruments has led the way in the industry for the last 25 years.

MATCHING PROCESS TO SOLUTION

Nucleonic Density Gauges enable miners, manufacturers and other parties in the industrial economy to know the exact density of a fluid of slurry in real time. Most conveniently, these instruments do not have to come into contact with the material and eliminate the chances of the solution sustaining damage. Plant administrators can apply density gauges in the following facilities:

- Dredging: When operating in conjunction with a flow meter, a density gauge delivers essential data on the dredger’s production rate. Whether the dredger is processing salt, sand, rare earth metals or other mining products, the system will provide accurate readings regardless.

- Processing plants: A density gauge solution can measure underflow and overflow density to determine if the separation and float tanks possess the correct density. These instruments can apply the same calculations to thickener and concentration tanks as well.

- Coal handling and preparation plants: During coal washing, managers can determine when the coal middlings were separated from the waste materials by measuring the slurry density.

- Mining specific solutions: The Thermo Scientific™ InterfacePRO Gauge is an option for precise level, density and interface measurements in the mining industry. Contact us today for more details.

Nuclear (Gamma) gauges distribute radioactive energy throughout tanks or other holding assets. These instruments calculate density by registering the amount of energy it receives after traveling throughout a confined space. SRO Technology’s technicians can communicate options to clients, tailored to your specific requirements.

THE IMPORTANCE OF PRECISION

Density gauges, no matter what their application, provide professionals with the information they need to assess processes.

For example, operations specialists can input density measurements into control system analysis programs. If the information is inaccurate, data scientists will draw incorrect conclusions. If leaders make decisions based on those deductions, the business may suffer as a result.

That’s why proper calibration is critical. When it comes to density gauges, the person installing the solution must understand the processes and impacts associated with the instrument’s accuracy. That’s why SRO Technology’s specialists account for several variables when implementing solutions, such as material properties and pipe thickness.

WHY SRO TECHNOLOGY?

Because many density gauges use nuclear gamma technologies to develop readings, authorised technicians are the only personnel who can work with such instruments. SRO Technology’s service experts have the correct licenses and industry knowledge necessary to install, repair and adjust density gauges.

Thanks to our nationwide locations, SRO Technology can attend to you needs no matter where you are in Australia. SRO technology also can offer AMDEL and other density gauge spares.

Our Solutions

Next Generation Geiger Counters

Read more

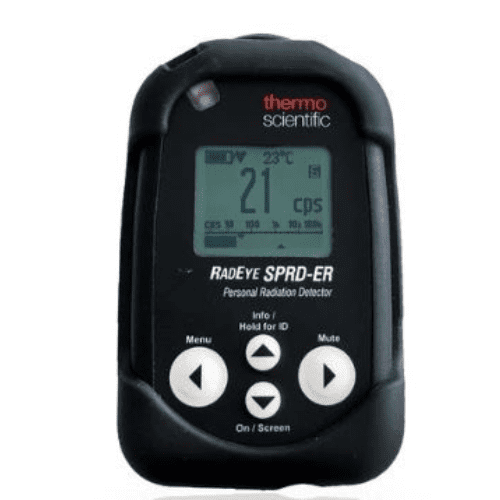

Protect first responders with the Thermo Scientific™ RadEye™ SPRD-ER Personal Radiation Detector. By providing significant detector sensitivity for search and find, combined with accurate high dose rate radiation measurement, the SPRD-ER is a suitable Geiger counter for all users and may be the only radiation detector you need

RadEye™ G20-10 and G20-ER10 X-Ray and Gamma Survey Meters

Read more

Nuclear medicine personnel who work with medical isotopes or in facilities that use radiation need to monitor their risk of exposure at all times. Protect employees and meet occupational safety regulations with the Thermo Scientific™ RadEye G20-10 and G20-ER10 X-ray and Gamma Survey Meters. These lightweight, compact Geiger counters are ideal for ambient equivalent dose and dose rate measurement, with a flat energy response curve from 17keV to 1.3MeV according to ambient equivalent dose H*(10). The RadEye G20-ER10 model covers the whole dose rate range from background to 100 mSv/h.

Frequently Asked Questions

How do nucleonic density gauges work?

Nucleonic density gauges work by emitting gamma radiation from a radioactive source through a material and measuring the intensity of radiation that reaches a detector on the opposite side. The attenuation of radiation intensity, as it passes through the material, is related to the material’s density, allowing for precise density measurements.

What are the applications of nucleonic density gauges?

These gauges are used in various industries, including mining and mineral processing, oil and gas, construction, chemical manufacturing, and waste management, for tasks such as measuring the density of slurries, drilling muds, soil, chemicals, and waste materials.

What advantages do nucleonic density gauges offer over other density measurement methods?

Advantages include non-contact measurement capability, high accuracy, the ability to measure through containers or piping, and fast response time, making them ideal for real-time monitoring and control in various industrial applications.

How is safety ensured when using radioactive materials in these gauges?

Safety measures include shielding the radioactive source, training operators, complying with regulatory requirements, and conducting regular maintenance to ensure the gauge’s safe operation.