News

Browse our articles

Ramsey Flex is Back

After months of behind-the-scenes development, SRO Technology is proud to announce the return of the trusted Ramsey Flex. Now re-released as Version 1.5 and available worldwide, the Flex is back and better than ever. A long-standing staple in materials...

SRO acquisition sees Ramsey products return to market

SRO Technology has acquired Ramsey and will be bringing this world-renowned brand and product range back to the market.

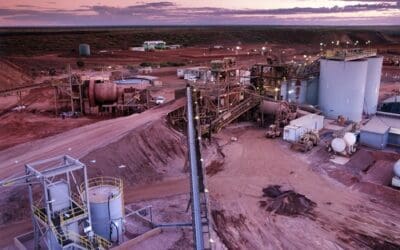

Innovative mining technologies used in Australia including belt weighers

The mining sector is continuing to evolve – and new technologies play an important role. Here are five of the most innovative technologies in the mining sector.

Three steps to maintaining accurate weightometers and feeders

When you run an industrial operation that relies on weightometers and feeder equipment, you need to make sure you take the right steps to guarantee their accuracy. By using SRO Technology’s weighing solution services, the three steps to more accurate equipment will become a breeze!

Why tramp metal detection in mining is more important than ever

In industries such as mining that rely on the processing of raw materials, tramp metal detection can help protect expensive machinery and personnel.

New base in Mackay to further improve local bulk measurement instrumentation service

We are dramatically improving our bulk measurement instrumentation service by opening a base in Mackay in Queensland. This will allow us to better support the mines in the Bowen Basin and power generating plants in the region. This expansion better enables us to...

3 key areas to check during an industrial site audit

Conducting a thorough audit of your industrial site can bring a number of potential issues to light, giving operators the chance to correct lingering problems.

Outdated equipment holding you back? Retrofitting may be the answer.

Legacy equipment can stand in the way of achieving optimal mining performance. Retrofitting outdated equipment is a cost-effective way to keep up with demand.

When does it make sense to use impact weighers?

Impact weighers can be incredibly beneficial when they are used correctly. Assess your facility’s needs to determine if this equipment is a good fit for you.

What a site audit can tell you about your mining operations

Comprehensive site audits are incredibly important for maintaining efficient and productive mining operations. Schedule your next review as soon as possible.

Why steel production centres need precise measuring instruments

Precise measuring equipment helps steel manufacturers ensure the right combination of materials are used and that finished products meet quality standards.

Why you need industrial equipment specific to your operations

Not all industrial equipment is appropriate for all applications. Here’s why you should only use machinery that has been designed for your type of business.

3 reasons tramp metal poses a major threat to mining operations

Tramp metal poses a significant threat to mining operations. These three issues, in particular, should convince site leaders to put proper safeguards in place.

What trends will drive the mining industry in 2020?

Take a look toward 2020 and the major trends that will drive Australia’s mining industry. Accounting for these trends now will help mining companies flourish.

3 signs you need an industrial site audit

Equipment performance issues could negatively impact your facilities output. Be on the lookout for these three signs that you need an industrial site audit.

Why the correct measurement of coal mine activity is important

Coal is an important and very big part of Australia’s economy. It’s the country’s second-largest export, with more than 70 active large mines in operation countrywide.

What should food manufacturers prioritise with their 2020 budgets?

Now is the time to start finalising your 2020 budget. Follow this guide to identify the top food processing priorities to budget for in the new year.

How to choose the right weigh belt feeder for your worksite

Every worksite has specific weigh belt feeder requirements, from the type of material being used to the level of accuracy needed in measurements.

Why you should lease industrial equipment in 2020

Leasing industrial equipment, rather than purchasing it outright, can provide more financial flexibility and a clearer outlook on future planning.

How to keep your industrial site running smoothly in 2020

Don’t let your site production fall behind the competition in 2020. Follow these tips to keep your industrial operations running smoothly all year long.

What to do when you’re having trouble detecting tramp metal

Don’t let tramp metal derail your industrial operations. Follow these steps if you are having trouble detecting tramp metal in your conveyor systems.

When should you finance your industrial equipment?

When is the time right to finance industrial equipment purchases? Read on to see when it makes the most sense to finance rather than buy in full.

How to keep your recycling plant running smoothly

Follow these tips to minimise operational challenges, prevent catastrophic failure and keep your recycling plant running without interruption.

Repair or replace: What to do when industrial equipment breaks down

Should you replace or repair malfunctioning machinery? Follow these tips so you always know the best way forward when your industrial equipment breaks down.

How to use proper maintenance to improve ROI on mining equipment

Mining companies may need to do more to ensure their heavy machinery holds up to the wear and tear of operations and extend the life of their equipment.

What are my options for financing new industrial equipment?

Securing industrial equipment is crucial to expanding operations – and businesses can get assets needed without affecting cash flow through equipment financing.

What makes industrial density measurement critical?

Density measurement measures liquid viscosity in numerous applications – what are the benefits of this process and why is it critical to industrial operations?

Which is better: a volumetric or gravimetric weigh belt feeder?

Determining whether a gravimetric and volumetric weigh belt feeder is better depends on your business’ unique industry, application and production system needs.

How to perfect solid flow measurement with impact weighing

Flow measurement is a critical part of many industrial and mining operations. It’s a process you can perfect with an impact weighing system.

Why integrators are key to an IoT-enabled mining system

The Internet of Things has vastly expanded the mining system capabilities – here’s why integrators are critical to smarter processing and production.