Level Measurement

Between controlling how much product is used in manufacturing and calculating how many materials an operation produces, level measurement systems are essential components of industrial operations.

SRO’s technicians and engineers are knowledgeable of the different level instruments on the market enabling us to choose specific solutions based on your operational needs, a key part of our design and installation services.

SELECTING THE APPROPRIATE SYSTEM

There is no single bin level indicator applicable to every process. For instance, while one type of sensor is capable of identifying moving targets in dusty conditions, another kind of instrument would register inaccurate measurements. A list of popular bin level detection devices are detailed below:

- Laser instruments provide accurate readings of various materials, from liquids to solids. Favoured for their contact-less functionality, these devices calculate measurements at any angle, and are used in the food, mining, power generation, chemicals, pulp and mining industries.

- Radar instruments are cheaper alternatives to laser options, but are often better suited to water and sewage applications. In general, operations that involve liquid measurement can make better use of these solutions.

- Ultrasonic instruments use sound pulses at a rate of four times per second to deduce the volume of liquid within a vat, bin or other holding asset. Because they do not require contact with the material, they are resistant to corrosion, coating or scaling other kinds of measuring devices contend with.

- Weight instruments require contact with products in order to calculate accurate readings. However, these devices can measure levels for both bulk solids and liquids, and are often favoured when handling pulp, pellets, mining material and the like

Based on the type of materials you’re handling, SRO’s technicians will recommend one of the four instruments and determine how to integrate them as part of a greater operation.

DEVELOPING AND DELIVERING SOLUTIONS

With the rights to design custom level measurement systems with instruments from Thermo Fisher C, Siemens, Vega and SICK, SRO’s specialists determine how these assets can serve as integral components of your operations. The key isn’t to adjust processes to accommodate new systems, but to configure devices to enhance plant performance.

Whenever developing solutions for our customers, SRO adheres to stringent quality assurance standards. With every endeavour we pursue, we must ensure our systems:

- Generate reliable, consistent results

- Are designed to withstand harsh production and extractive environments

- Add value to your operations

- Thanks to our brand-agnostic capabilities and willingness to learn about your operations, SRO delivers stellar services you can rely on from the moment you contact us

Our Solutions

Retrofit Bin Weighing

Read more

Ramsey™ C-Level Continuous Level Indicator

Eliminate failure and maintenance issues with your inventory monitoring and process control system with the Thermo Scientific™ Ramsey™ C-Level Continuous Level Indicator. Ideally suited for bulk solids or liquids, the Ramsey C-Level Continuous Level Indicator monitors inventory and process control during load-out or filling. With its unique precision strain gauge sensors press-fit into the support structure, the Ramsey C-Level Continuous Level Indicator can operate without concern for failure or maintenance issues caused by the monitored material or process environment. This distinctive design also compensates for temperature changes that can affect the accuracy of bolt-on strain sensors.

Features and benefits

- Accuracy to within ±2%

- Resistance to corrosive or abrasive materials, uneven material discharge, build-up on sidewalls,

- Bridging, rat-holing or dusting

- Precision electronic strain sensing with hermetically-sealed stainless steel strain sensor

- External sensor mounted to the bin to eliminate contamination or corrosion

- Incorporated sensor to eliminate temperature effects common to “bolt-on” sensor

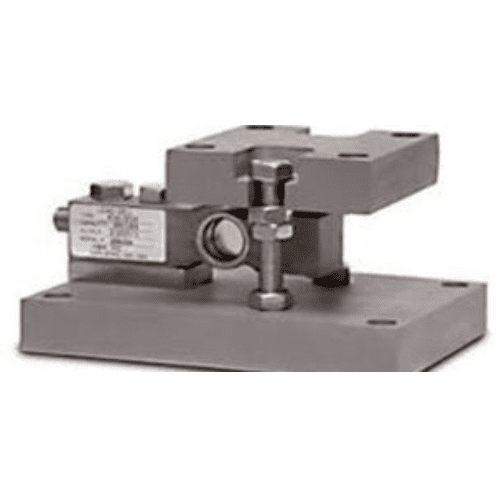

Loadcell Bin Weighing

Read more

If you are at project stage or you need higher accuracy than the conventional bolt on solutions, SRO technology can help.

SRO Technology has a number of skilled engineers who are familiar with Loadcell bin weighing systems.

The benefits of using SRO are:

- Provision of help and advice on the best most cost effective solution

- Calculate the requirements and best fit with one of our NMI Verifiers to produce a high accuracy solution

- Provide best in class loadcell and display packages for your particular application

- Install and commission the solution and support it moving forwards.